In CCMT 2024 (China CNC Machine Tool Fair), we have a great time with domestic and overseas clients. Wish you have witnessed the quality of our machines. We sincerely recruit distributors for overseas market. Our cost-effective Machining Centers will increase your company’s revenue and bring satisfaction to your clients. Welcome to contact Soy for more details. The new model of our QVF 5 axis series:has HSKA63/20000rpm electric spindle, Huazhong control system, Mineral body. Nice to meet you all here.

Good news! We will attend the China CNC Machine Tool Fair 2024 in Shanghai next month. Sincerely invite you to attend this exhibition to see Qiaobo tech’s Machining centers. Welcome to contact me if you have interests of this exhibition or any new inquiries.

On August 1, 2023, the completion ceremony of Chongqing Qiaobai Intelligent Technology Co., Ltd. was successfully held in Yongchuan district, Chongqing, China. Wen Song – Member of the Standing Committee of the CPC Yongchuan District Committee; Deputy head of the Yongchuan district government; Secretary of the Party Working Committee of Yongchuan High tech Zone. Kui Sheng – Deputy secretary of the Party Working Committee and Director of the management committee of Yongchuan High tech Zone. Heping Deng – Member of the Party Working Committee of Yongchuan High tech Zone; Secretary and director of the Party Working Committee of Phoenix Lake Industrial Promotion Center of Yongchuan High tech Zone. Kefeng Xie – Member and deputy director of the Party Working Committee of Yongchuan High tech Zone. Takeda – head of NC business of Mitsubishi Electric (China) Co., Ltd. Our chairman and general manager – Jiandong Liu attended the event. Chairman Liu Jiandong delivered a speech and welcomed the arrival of leaders and entrepreneurs. He stated that Chongqing Qiaobai Intelligent Technology Co., Ltd. will continue to play a bridging role in innovating and promoting mechanical intelligent equipment in the southwest region, exploring innovation, working solidly, facing challenges, seizing opportunities, and creating greater achievements. Takeda expressed his gratitude to Chongqing Qiaobo for years of support, trust and cooperation, and hoped to continue to seek common development in the future. During the event, Wen Song pointed out that in Sichuan and Chongqing area, Yongchuan district has the advantages of being handed down from left to right, connecting the east and the west. He expressed his gratitude to all entrepreneurs for their love for Yongchuan district, which has made significant contributions to the intelligent equipment industry in china western region. He hopes that intelligent equipment enterprises strive for self-reliance and perseverance, and promote the development of Yongchuan’s intelligent equipment industry to achieve new leaps step up to a new level, create Chinese high-end CNC machine tools, and achieve “good machine tools, Yongchuan made”. Everyone witness the successful completion of Chongqing Qiaobo Intelligent Technology Co., Ltd.’s intelligent equipment production base.

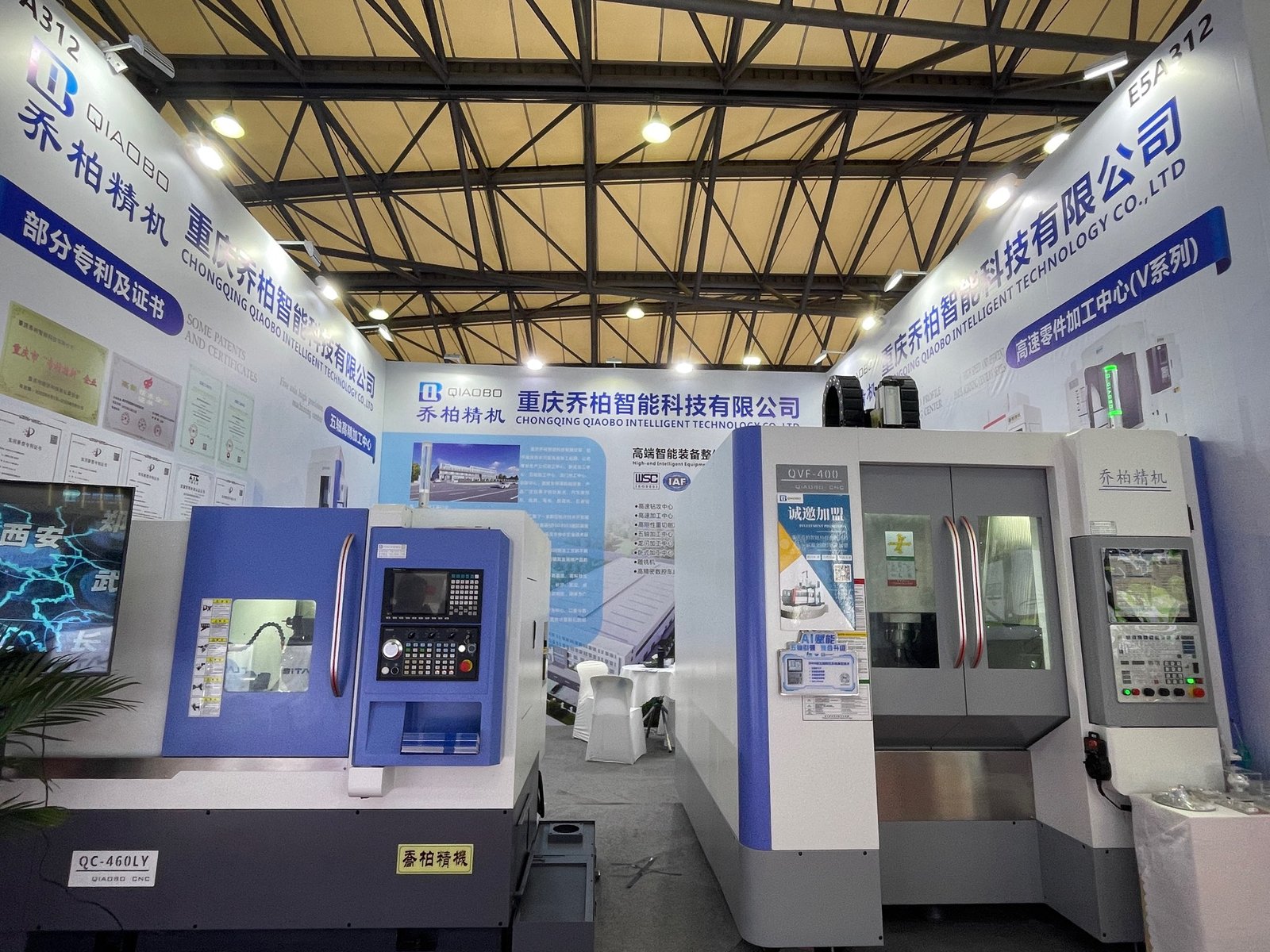

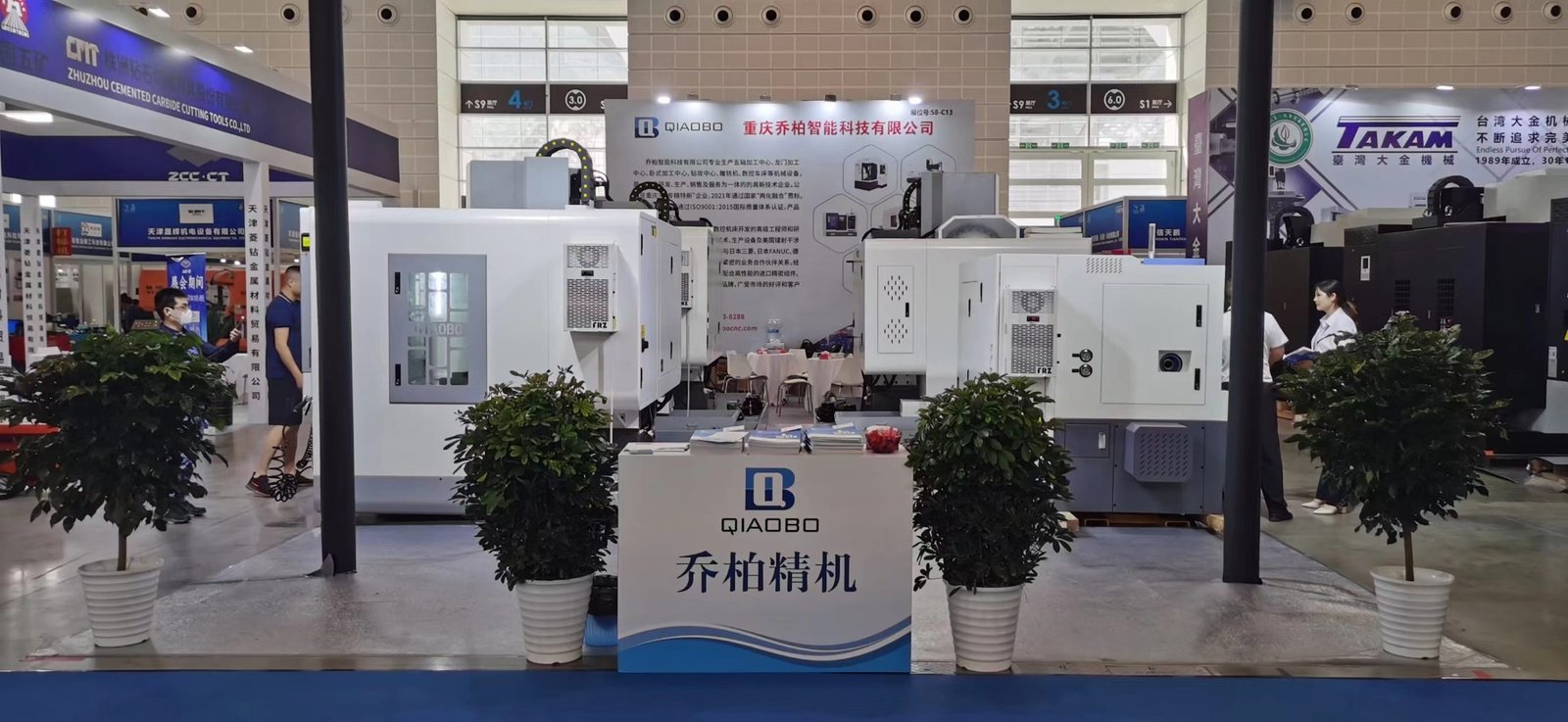

From March 16th to 19th, 2023, let’s meet at the Xi’an Industrial Intelligent Equipment exhibition. At that time, Qiaobo Intelligent Technology Company will bring a series of products to participate in the exhibition as below fro reference: V-855 High speed parts processing center The rapid displacement speed of the XYZ axis is 48/48/48 m/min Spindle speed: 10000RPM (or 12000/15000RPM) Tool change speed T~T: 1.8 seconds Precision Spindle: BT-40 The base adopts an A-shaped rib structure layout to improve the seismic absorption effect, and the overall iron parts adopt a box design to achieve high bending rigidity. The structure adopts advanced cast iron material, which is tempered to eliminate internal stress, ensuring the best rigidity, accuracy, and durability. The high rigidity structure originates from the accumulation of years of experience data and the rationalization of the slenderness ratio design of the mechanism, improving the compression and lateral bending resistance of iron parts. The design of a high-speed tool changing mechanism, combined with pre induction control and an efficient tool changing system, enables tool changing work. V-850C (mineral bed) The rapid displacement speed of the XYZ axis is 48/48/48 m/min Spindle speed: 12000 RPM (or 16000/20000 RPM) Tool change speed T~T: 1.6 seconds Precision Spindle: BT-40 Adopting a high-speed electric spindle with a main spindle of 20000 revolutions and a high-speed BBT-40 (HSK63) electric spindle, it has low vibration, good stability, three axis full closed-loop control, and high accuracy. The constant power of the electric spindle is 15KW, with a maximum power of 18.5KW. The BBT-40 spindle has higher accuracy, faster processing efficiency, and good results. V-1160 The rapid displacement speed of the XYZ axis is 36/36/36 m/min Spindle speed: 10000RPM (or 12000/15000RPM) Tool change speed T~T: 1.8 seconds Good choice for precision molds and product processing The electrical box adopts constant temperature air conditioning to ensure that the cabinet is in a closed and constant temperature state for a long time, extending the service life of the electrical appliances. The spindle adopts a constant temperature oil cooler to ensure that it does not generate high temperatures due to heavy cutting or high-speed rotation, extending the service life and accuracy of the spindle. Adopting a dual filtered water and 10L air storage tank device, ensuring the stability of knife changing and allowing for continuous replacement of three knives in the event of gas stoppage. Adopting a forward flushing and back flushing method, it is convenient to clean iron filings and is not leaking water. The water tank adopts a hidden pipeline design to avoid pipeline entanglement, which is both beautiful and clean. The transmission components are all imported, with high accuracy and good stability. QC-5052 Maximum spindle speed: 4200RPM Taiwan precision spindle with 8-inch precision chuck The independent hydraulic station design maximizes the convenience of maintenance and operation, effectively improving the heat dissipation effect of the hydraulic system. The enclosed waterproof design effectively protects components such as screw rods and guide rails. All sliding plates, spindle tables, turrets, and guide rail base contact surfaces are scraped with long shovels to achieve optimal assembly accuracy, structural rigidity, and balanced load. Adopting high-precision NSK bearings from Japan

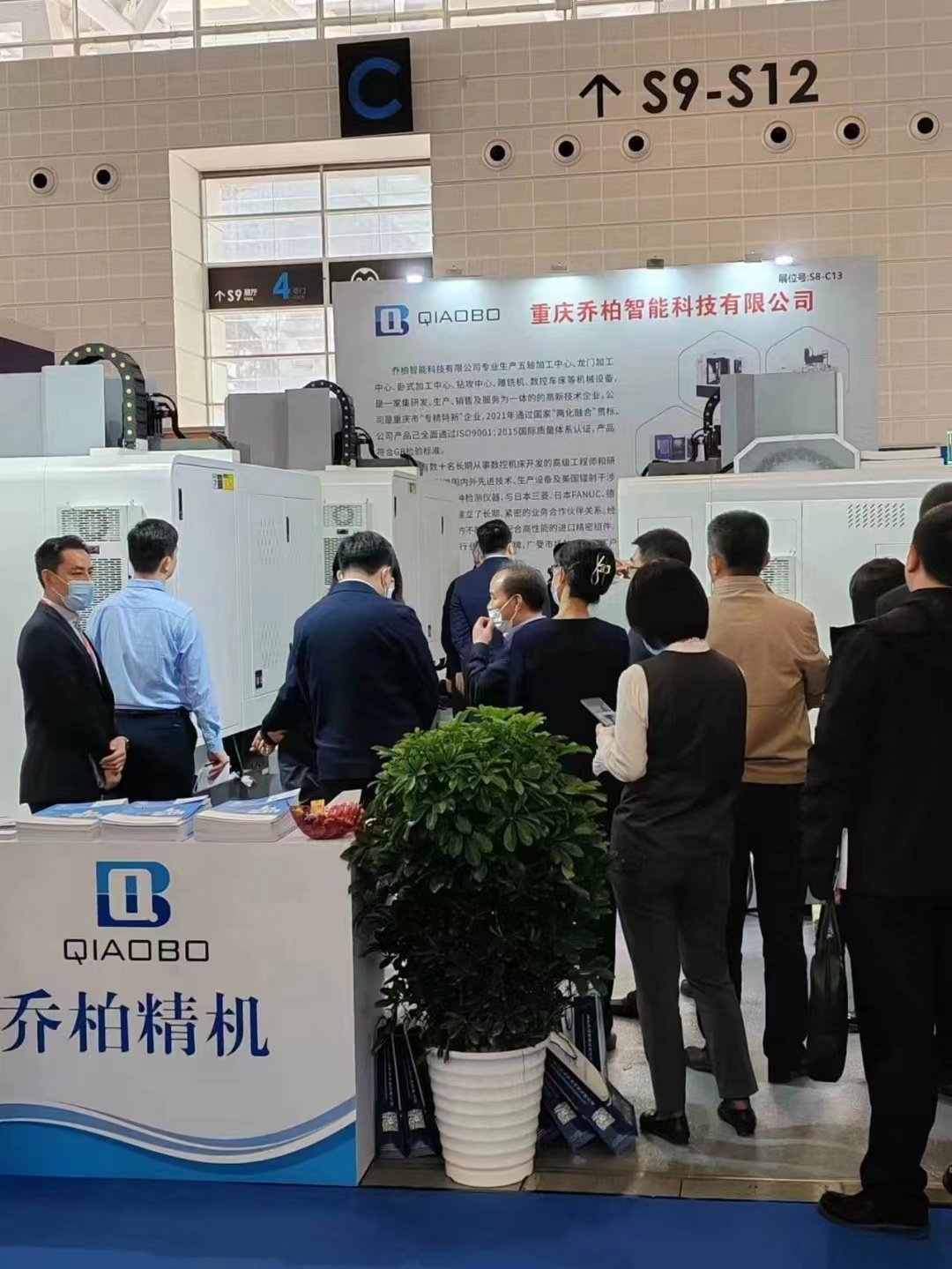

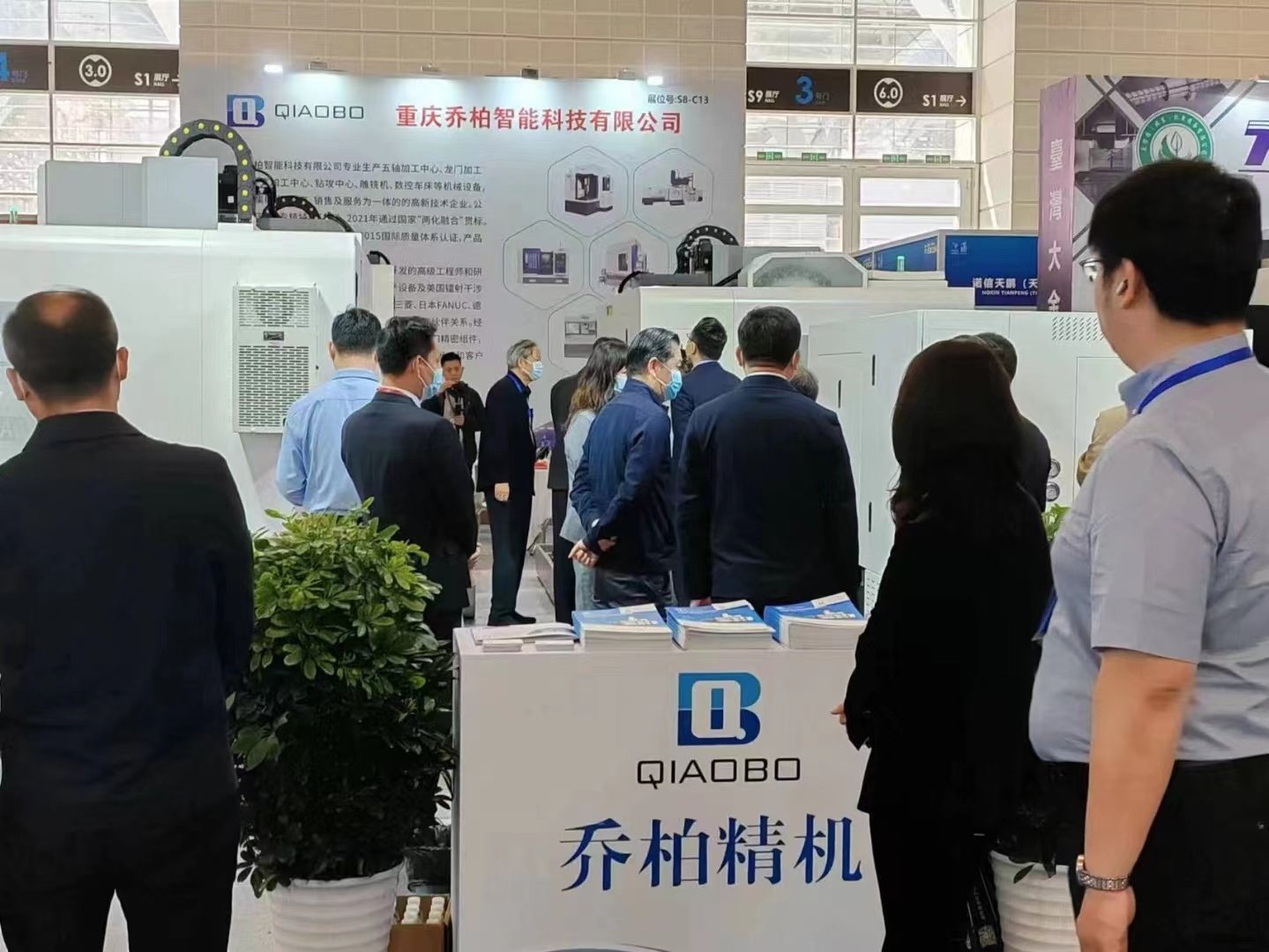

On the morning of May 8, 2023, Chongqing Qiaobo Intelligent Technology Co., Ltd was invited to participate in the 19th China Tianjin International Equipment Manufacturing Expo. The Vice Mayor of Tianjin — Bing Yang with a delegation visited our company’s Tianjin booth to conduct research and guidance work. General Manager Jiandong Liu accompanied the visit and had communication with Bing Yang. Liu warmly welcomed the arrival of Vice Mayor Yang Bing and his delegation, and provided a detailed introduction to our company’s development history, current development status, and strategic planning. Chongqing Qiaobo Intelligent Technology Co., Ltd located in the beautiful Phoenix Lake Industrial Park, Yongchuan District, Chongqing. We we specialized in producing Vertical machining center, Five axis machining center, Gantry machining center, Drilling and tapping center, Engraving and milling machine center, CNC machine tool and other mechanical equipment. We are a high-tech enterprise integrating research and development, manufacture, sales and service. Qiaobo company is a specialized, refined, and innovative enterprise in Chongqing, which passed the national integration and standardization in 2021. Our products have fully passed the ISO9001-2015 international quality system certification and meet the GB inspection standards. Our products are widely used in aerospace, medical, electronics, 5G communications, engineering machinery, oil drilling, auto parts, machinery processing and other industries. Bing Yang highly praised our company’s exhibition machines (V-855, V-1160, QC-460L) and expressed the hope that Qiaobo tech can continue to innovate, make good use of our own characteristics and advantages, vigorously expand the northern market, continuously improve enterprise efficiency and core competitiveness, and make new contributions.

May is a season full of vitality, a good time for people to travel, and also a season that requires us to work hard. In the past days, we have known that Qiaobo’s development path can’t be separated from your cooperation and support. Long term union, growing year by year. We sincerely invite you to participate in the 23rd Lijia International Intelligent Equipment Exhibition (May 11-14, 2022), where we will discuss friendship and seek common development. The participating models are as follows: V-850A(Mineral casting machine bed)Good choice for precision mold and high precision product processingThe rapid displacement speed of the XYZ axis is 48/48/48 m/min. Tool change speed T-T: 1.6 s. Spindle speed: 12000/16000/20000 RPM. Precision spindle: BT-40 V-855The rapid displacement speed of the XYZ axis is 48/48/48 m/min. Tool change speed T-T: 1.8 s. Spindle speed: 10000/12000/15000 RPM. Precision spindle: BT-40 V-1160The rapid displacement speed of the XYZ axis is 36/36/36 m/min. Tool change speed T-T: 1.8 s. Spindle speed: 10000/12000/15000 RPM. Precision spindle: BT-40 QVF-650The rapid displacement speed of the XYZ axis is 24/24/24 m/min. Tool change speed T-T: 1.8 s. Spindle speed: 20000 RPM. Precision spindle: BT-40